Sikadur-42 MP Slow

Sikadur-42 MP Slow is a three-component, multipurpose, moisture tolerant, epoxy grouting system. For use at temperatures between +20 °C and +40 °C.

- High early strength

- Ready-to-mix, pre-batched units

- Moisture tolerant

₨ 44,100 ₨ 49,000

Usage

High-strength grouting and fixing of:

- Starter bars

- Anchors

- Fasteners

- Tie rods

- Crash barrier posts

- Fence and railing posts

Under-grouting and bedding of:

- Base plates

- Machine bases, seat base-plates for light and heavy machinery including heavy impact and vibratory machinery, reciprocating engines, compressors, pumps, presses, etc.

- Bridge bearings

- Mechanical joints (i.e. road/bridge/deck types etc.)

- Crane tracks

Advantages

- High early strength

- Ready-to-mix, pre-batched units

- Moisture tolerant

- Non-shrink

- Corrosion and chemically resistant

- Stress and impact resistant

- High compressive strength

- High vibration resistance

- Low coefficient of thermal expansion

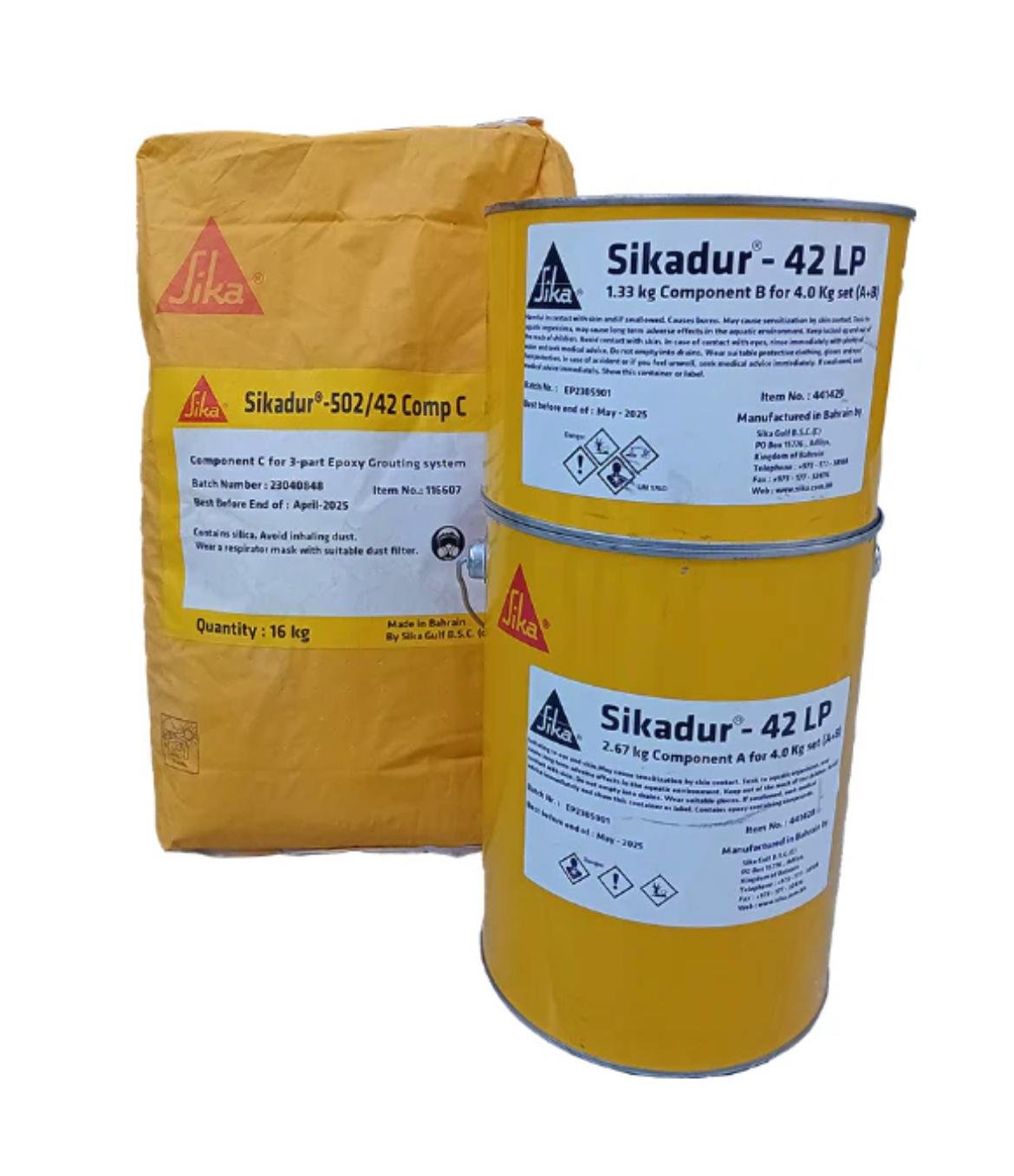

Packaging

Pre-batched unit 12 kg (A+B+C) pallets of 252 kg (21 × 12 kg)

Bulk packaging (not pre-batched) 144 kg (A+B+C) Component C (Sikadur-514) bag for 24 kg units pallets of 960 kg (40 × 24 kg)

Colour

Concrete Grey

Mixing Ratio

Component A : B : C = 5 : 1 : 30 by weight (Standard)

Solid / liquid = 5 : 1 by weight

Possibility to adjust the mixing ratio, depending on flowability:

Component A : B : C = 5 : 1 : (27–36) by weight

Solid / liquid = (4.5–6) : 1 by weightLayer Thickness

Minimum grout depth: 10 mm

Maximum grout depth: 150 mmTemperature Layer thickness max. 20 °C–30 °C 150 mm 30 °C–40 °C 100 mm* * no reduction of fillers; apply only with Mixing Ratio A : B : C = 5 : 1 : (30–36)

Peak Exotherm

41 °C (at +23 °C) (ASTM D 2471) Product Temperature

Sikadur-42 MP Slow must be applied at temperatures between +20 °C and +30 °C

Condition the material by also storing at this temperature for 48 hours before use.Ambient Air Temperature

+20 °C min. / +40 °C max.

Dew Point

Substrate temperature during application must be at least 3 °C above dew point to avoid condensation.

Substrate Temperature

+20 °C min. / +40 °C max

There are no reviews yet.